R-XPT Throughbolt

Throughbolt for non-cracked concrete

Features and benefits

- High performance in non-cracked concrete confirmed by ETA Option 7

- High quality with cost effectiveness

- Suitable for reduced embedment to avoid contact with reinforcement

- Embedment depth markings help to ensure precise installation of the anchor

- Design allows drilling and installing directly through the fixture and helps to reduce installation effort

- Cold formed body ensures consistent dimensional accuracy

- Simple through-installation (drilling and installation through fixed material)

- Optimized expander design with six grip features allows for a high load-bearing capacity

Product information

Size |

Product Code |

Approval type |

Anchor |

Fixture |

|||

Diameter |

Length |

Max. thickness tfix for: |

Hole diameter |

||||

d |

L |

hnom,red |

hnom,std |

df |

|||

- |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

M6 |

R-XPT-06050/10 |

AT-15-9327/14 |

6 |

50 |

10 |

- |

7 |

R-XPT-06065/5 |

AT-15-9327/14 |

6 |

65 |

25 |

5 |

7 |

|

R-XPT-06085/25 |

AT-15-9327/14 |

6 |

85 |

45 |

25 |

7 |

|

R-XPT-06100/40 |

AT-15-9327/14 |

6 |

100 |

60 |

40 |

7 |

|

M8 |

R-XPT-08050/5 |

AT-15-9327/14 |

8 |

50 |

5 |

- |

9 |

R-XPT-08060/10 |

ETA 17/0183 |

8 |

60 |

10 |

- |

9 |

|

R-XPT-08065/15 |

ETA 17/0183 |

8 |

65 |

15 |

- |

9 |

|

R-XPT-08075/10 |

ETA 17/0183 |

8 |

75 |

25 |

10 |

9 |

|

R-XPT-08080/15 |

ETA 17/0183 |

8 |

80 |

30 |

15 |

9 |

|

R-XPT-08085/20 |

ETA 17/0183 |

8 |

85 |

35 |

20 |

9 |

|

R-XPT-08095/30 |

ETA 17/0183 |

8 |

95 |

45 |

30 |

9 |

|

R-XPT-08115/50 |

ETA 17/0183 |

8 |

115 |

65 |

50 |

9 |

|

R-XPT-08140/75 |

ETA 17/0183 |

8 |

140 |

90 |

75 |

9 |

|

R-XPT-08150/85 |

ETA 17/0183 |

8 |

150 |

100 |

85 |

9 |

|

M10 |

R-XPT-10065/5 |

ETA 17/0183 |

10 |

65 |

5 |

- |

12 |

R-XPT-10080/10 |

ETA 17/0183 |

10 |

80 |

20 |

10 |

12 |

|

R-XPT-10095/25 |

ETA 17/0183 |

10 |

95 |

35 |

25 |

12 |

|

R-XPT-10115/45 |

ETA 17/0183 |

10 |

115 |

55 |

45 |

12 |

|

R-XPT-10130/60 |

ETA 17/0183 |

10 |

130 |

70 |

60 |

12 |

|

R-XPT-10140/70 |

ETA 17/0183 |

10 |

140 |

80 |

70 |

12 |

|

R-XPT-10150/80 |

ETA 17/0183 |

10 |

150 |

90 |

80 |

12 |

|

R-XPT-10180/110 |

ETA 17/0183 |

10 |

180 |

120 |

110 |

12 |

|

M12 |

R-XPT-12080/5 |

ETA 17/0183 |

12 |

80 |

5 |

- |

14 |

R-XPT-12100/5 |

ETA 17/0183 |

12 |

100 |

25 |

5 |

14 |

|

R-XPT-12120/25 |

ETA 17/0183 |

12 |

120 |

45 |

25 |

14 |

|

R-XPT-12125/30 |

ETA 17/0183 |

12 |

125 |

50 |

30 |

14 |

|

R-XPT-12135/40 |

ETA 17/0183 |

12 |

135 |

60 |

40 |

14 |

|

R-XPT-12140/45 |

ETA 17/0183 |

12 |

140 |

65 |

45 |

14 |

|

R-XPT-12150/55 |

ETA 17/0183 |

12 |

150 |

75 |

55 |

14 |

|

R-XPT-12160/65 |

ETA 17/0183 |

12 |

160 |

85 |

65 |

14 |

|

R-XPT-12180/85 |

ETA 17/0183 |

12 |

180 |

105 |

85 |

14 |

|

R-XPT-12200/105 |

ETA 17/0183 |

12 |

200 |

125 |

105 |

14 |

|

R-XPT-12220/125 |

ETA 17/0183 |

12 |

220 |

145 |

125 |

14 |

|

R-XPT-12250/155 |

ETA 17/0183 |

12 |

250 |

175 |

155 |

14 |

|

R-XPT-12280/185 |

ETA 17/0183 |

12 |

280 |

205 |

185 |

14 |

|

M16 |

R-XPT-16090/10 |

- |

16 |

90 |

0 |

0 |

18 |

R-XPT-16100/5 |

ETA 17/0183 |

16 |

100 |

5 |

- |

18 |

|

R-XPT-16105/10 |

ETA 17/0183 |

16 |

105 |

10 |

- |

18 |

|

R-XPT-16125/5 |

ETA 17/0183 |

16 |

125 |

25 |

5 |

18 |

|

R-XPT-16140/20 |

ETA 17/0183 |

16 |

140 |

40 |

20 |

18 |

|

R-XPT-16150/30 |

ETA 17/0183 |

16 |

150 |

50 |

30 |

18 |

|

R-XPT-16160/40 |

ETA 17/0183 |

16 |

160 |

60 |

40 |

18 |

|

R-XPT-16180/60 |

ETA 17/0183 |

16 |

180 |

80 |

60 |

18 |

|

R-XPT-16200/80 |

ETA 17/0183 |

16 |

200 |

100 |

80 |

18 |

|

R-XPT-16220/100 |

ETA 17/0183 |

16 |

220 |

120 |

100 |

18 |

|

R-XPT-16250/130 |

ETA 17/0183 |

16 |

250 |

150 |

130 |

18 |

|

R-XPT-16280/160 |

ETA 17/0183 |

16 |

280 |

180 |

160 |

18 |

|

R-XPT-16300/180 |

ETA 17/0183 |

16 |

300 |

200 |

180 |

18 |

|

M20 |

R-XPT-20125/5 |

ETA 17/0183 |

20 |

125 |

5 |

- |

22 |

R-XPT-20160/20 |

ETA 17/0183 |

20 |

160 |

40 |

20 |

22 |

|

R-XPT-20200/60 |

ETA 17/0183 |

20 |

200 |

80 |

60 |

22 |

|

R-XPT-20250/110 |

ETA 17/0183 |

20 |

250 |

130 |

110 |

22 |

|

R-XPT-20300/160 |

ETA 17/0183 |

20 |

300 |

180 |

160 |

22 |

|

M24 |

R-XPT-24180/20 |

AT-15-9327/14 |

24 |

180 |

35 |

20 |

26 |

R-XPT-24260/100 |

AT-15-9327/14 |

24 |

260 |

115 |

100 |

26 |

|

R-XPT-24300/140 |

AT-15-9327/14 |

24 |

300 |

155 |

140 |

26 |

|

Base material

-

Non-cracked concrete C20/25-C50/60

-

Unreinforced concrete

-

Reinforced concrete

For use also with

-

Natural Stone (after site testing)

Applications

- Cladding restraint

- Curtain wall

- Balustrading

- Barriers

- Handrails

- Racking

- Structural steel

- Bollards

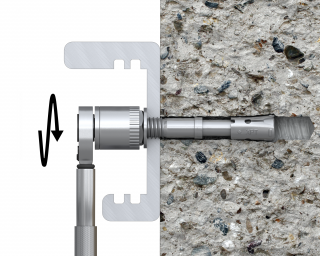

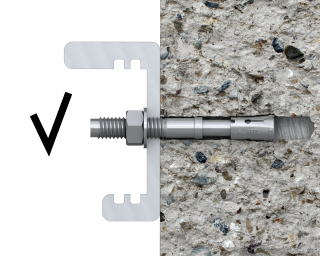

Installation guide

- Drill a hole of required diameter and depth

- Clear the hole of drilling dust and debris (using blowpump or equivalent method)

- Lightly tap the throughbolt through the fixture into hole with a hammer, until fixing depth is reached

- Tighten to the recommended torque

Installation data

Size |

M6 |

M8 |

M10 |

M12 |

M16 |

M20 |

M24 |

||

Thread diameter |

d |

[mm] |

6 |

8 |

10 |

12 |

16 |

20 |

24 |

Hole diameter in substrate |

d0 |

[mm] |

6 |

8 |

10 |

12 |

16 |

20 |

24 |

Installation torque |

Tinst |

[Nm] |

5 |

15 |

30 |

50 |

100 |

200 |

300 |

Wrench size |

Sw |

[mm] |

10 |

13 |

17 |

19 |

24 |

30 |

36 |

External diameter of washer |

[mm] |

12 |

16 |

20 |

24 |

30 |

37 |

44 |

|

STANDARD EMBEDMENT DEPTH | |||||||||

Min. hole depth in substrate |

h0,s |

[mm] |

55 |

65 |

69 |

90 |

110 |

129 |

140 |

Min. installation depth |

hnom,s |

[mm] |

50 |

55 |

59 |

80 |

100 |

119 |

135 |

Min. substrate thickness |

hmin,s |

[mm] |

84 |

100 |

100 |

136 |

170 |

198 |

224 |

Min. spacing |

smin, s |

[mm] |

45 |

50 |

55 |

75 |

90 |

140 |

180 |

Min. edge distance |

cmin, s |

[mm] |

50 |

40 |

50 |

65 |

80 |

100 |

200 |

REDUCED EMBEDMENT DEPTH | |||||||||

Min. hole depth in substrate |

h0,r |

[mm] |

35 |

50 |

59 |

70 |

90 |

110 |

125 |

Min. installation depth |

hnom,r |

[mm] |

30 |

40 |

49 |

60 |

80 |

100 |

120 |

Min. substrate thickness |

hmin,r |

[mm] |

80 |

100 |

100 |

100 |

130 |

158 |

194 |

Min. spacing |

smin,r |

[mm] |

40 |

45 |

55 |

100 |

100 |

125 |

160 |

Min. edge distance |

cmin,r |

[mm] |

45 |

40 |

65 |

100 |

100 |

125 |

160 |