R-SL-TK High Temperature Silicone

High-temperature silicone – One-component elastic sealant with acetate curing system.

Features and benefits

- The seal possesses complete and long-term resistance to oils, petrol, grease, diesel & coolants.

- Resistant to changeable weather conditions, temperature extremes (up to 350°C) and UV radiation.

- Highly and permanently elastic sealing properties

Base material

-

Glass

-

Protected metals (aluminium, brass, copper, steel, zinc-plated metal sheet)

-

Ceramics

-

Glaze

-

Concrete

-

Masonry

-

Plastics

-

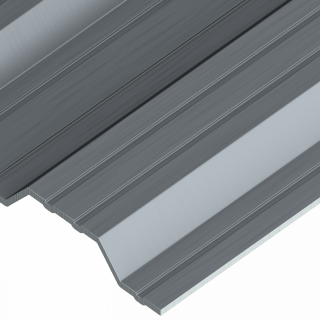

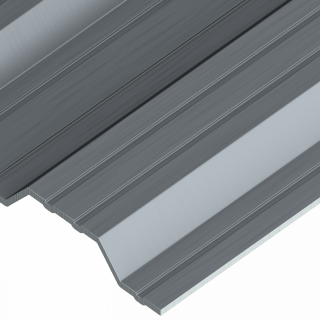

Metal Sheet & Profiles

For use also with

-

Terracotta

-

PVC Profile

-

High-Density Natural Stone

-

Metal Sheet & Profiles

-

Stainless Steel

-

Solid Brick

-

Hollow Brick

-

Solid Sand-lime Brick

Applications

- Sealing in high-temperature environments: furnaces, chimneys, heating installations, combustion & flue ducts, ventilation and air-conditioning systems.

- Fixing of elements in domestic fireplaces and industrial furnaces.

Installation guide

- The surface, that silicone will be apllied on, should be clean, free of dust, grease, rust, remains of old seal and other substances that might weaken the cohesion.

- Prior to application of silicone protect edges with masking tape

- Cut the tip of the cartridge, leaving part of the thread. Screw the applicator on to the thread, then cut at the required angle to give an aperture width suited to the joint.

- Use manual or pneumatic gun applicator.

- Applied silicone may be smoothed with a spatula or similar tool. Moisten the spatula first in special wetting agent or detergent solution.

- The silicone hardens by reaction with moisture from the air, so ensure well-ventilated conditions.

- After completing the application, wipe tools with a paper towel and clean with solvent.