R-SL-LUS Mirrors Adhesive Silicone

Silicone adhesive for mirrors - Solvent-free, colourless adhesive with neutral curing system.

Features and benefits

- Intended for non-invasive fixing and adhesion of mirrors and glass mosaics.

- Excellent adhesion to most materials and substrates used in construction.

- Texture and colour suitable for use for sealing mirror edges.

- Warranty covers against discolouration of base materials.

Base material

-

Glass

-

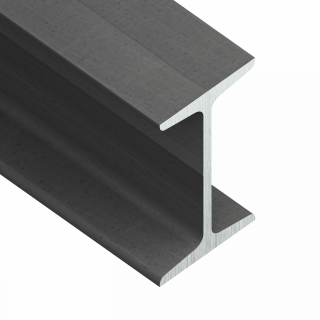

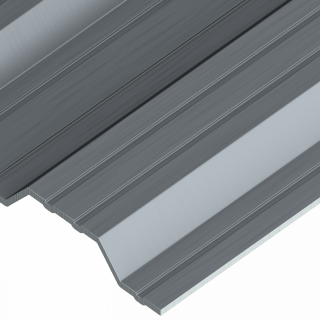

Metal Sheet & Profiles

-

Stainless Steel

-

Glaze

-

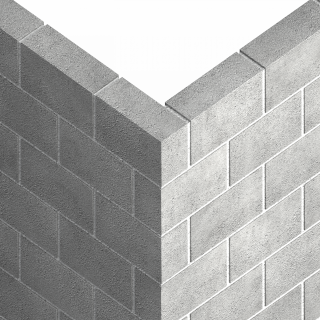

Masonry

-

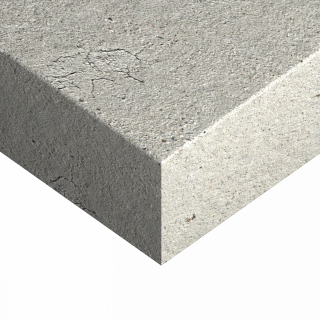

Concrete

-

.png)

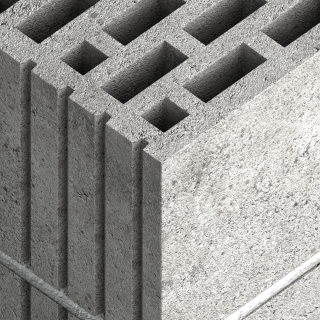

Aerated Concrete Block

-

Plastics

-

Cement Mortar

-

Protected wood

-

Mirrors

-

Protected metals (aluminium, brass, copper, steel, zinc-plated metal sheet)

For use also with

-

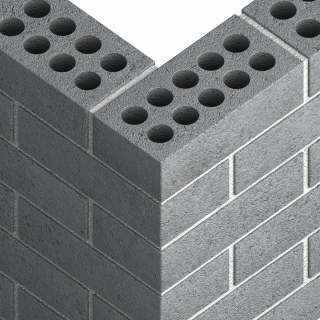

Solid Concrete Block

-

Hollow-core Slab

-

Concrete Slab

-

Lightweight Concrete Block

-

Hollow Lightweight Concrete Block

-

Silicate Blocks

-

High-Density Natural Stone

-

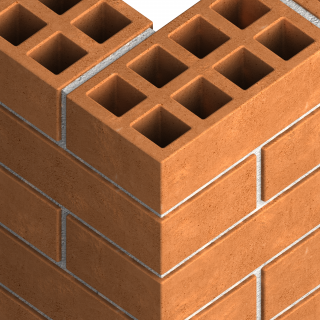

Hollow Brick

-

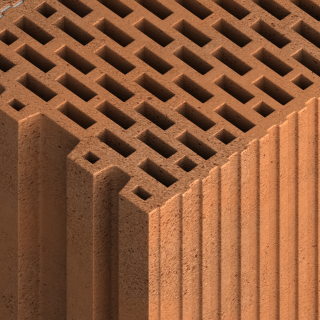

Vertically-perforated Clay Block

-

Hollow Sand-lime Brick

-

Solid Brick

-

Solid Sand-lime Brick

-

Ceramic Hollow Block

-

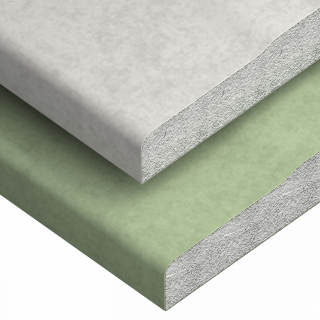

Gypsum Fibreboards

-

Plasterboard

-

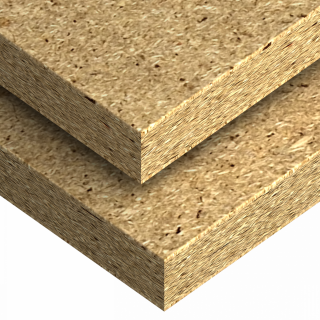

Chipboard

-

Oriented Strand Board

-

Stainless Steel

Applications

- Adhesion of decorative mirrors to varied substrates, even at low temperatures (5°C).

- Fixing mirror mosaics (mirror-mirror bonding) in shower cabinets.

- Adhesion of mirrors to substrates exposed to vibration and stress (new-build environments).

- Fixing mirrors and large glass panels such as Lacobel (e.g. on sliding wardrobe doors).

- Grouting mirrors edges (subsequent to full hardening of the pre-applied adhesive).

- Adhesion of mirrors with metal, wood or plastic frames.

- External fixing of glass components

Installation guide

- Prior to application of silicone protect edges with masking tape

- Cut the tip of the cartridge, leaving part of the thread. Screw the applicator on to the thread, then cut at the required angle to give an aperture width suited to the joint.

- Use manual or pneumatic gun applicator.

- The product should be applied in parallel, vertical streaks or in dispersed spots, in order to facilitate evaporation of by-products during curing. Do not seal edges of the mirror until after the silicone is fully-hardened.

- Depending on the mirror size and weight, additional support may be required throughout the bonding period and for several hours thereafter. If using mirrors from an unrecognised manufacturer, checks must be performed before installation to ensure suitability. The mirror should be secured in accordance with EN 1036 - Glass in building.