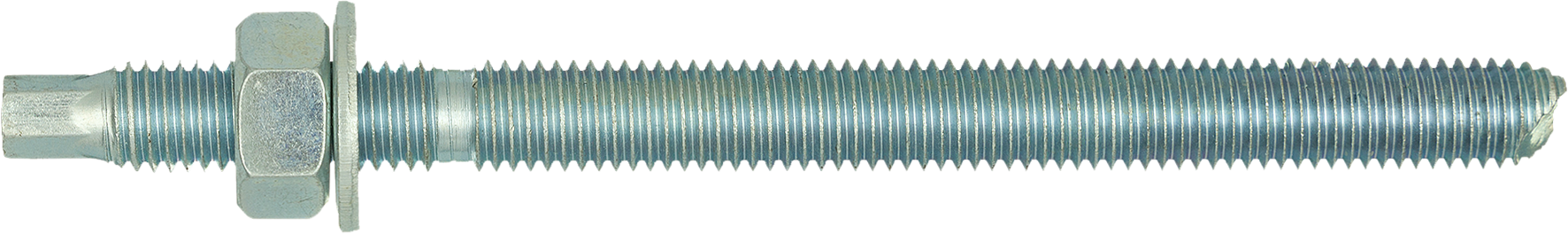

R-KEX-I HIGH-PERFORMACE EPOXY RESIN THREADED RODS

High performance pure epoxy resin approved for cracked and non-cracked concrete. Available in Asia-Pacific region.

Features and benefits

- High-performance epoxy resin for concrete.

- Approved for use with threaded rods for use in non-cracked concrete (EAD 330499-00-0601).

- Suitable for use in dry and wet substrates including flooded holes (use category I1 & I2).

- Installation direction D3 (downward and horizontal and upwards installation).

- Very high chemical resistance – suitable for applications exposed to influence of various agents (industrial or marine environment).

- Extended working time ensures easy installation of metal components (up to 50 min. in 20°C).

- Working with Dustlessdrill - drlling and hole cleaning in one step.

- Wide offer of rods under diameters and types of anticorrosive coating: A4, ZP, HDG, ZF and HCR.

- High Corrosion Resistant (HCR) steel rods for damp and aggressive conditions.

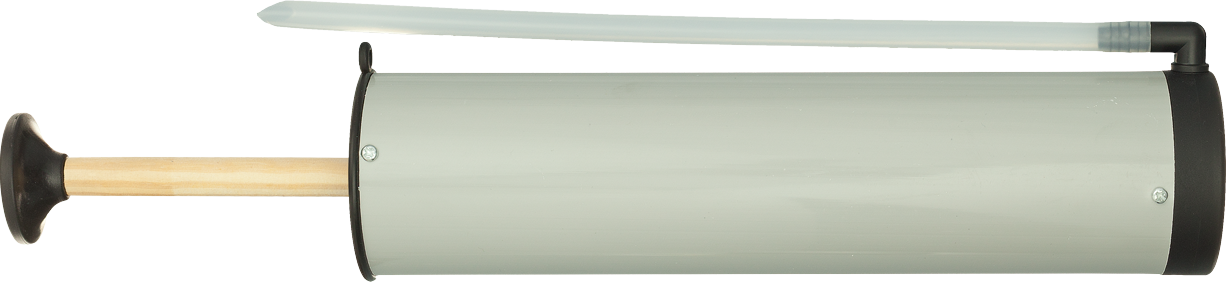

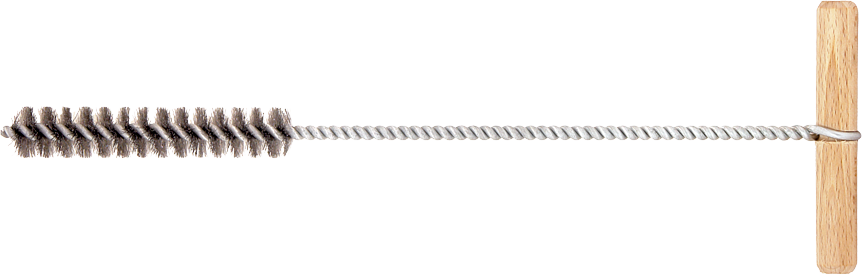

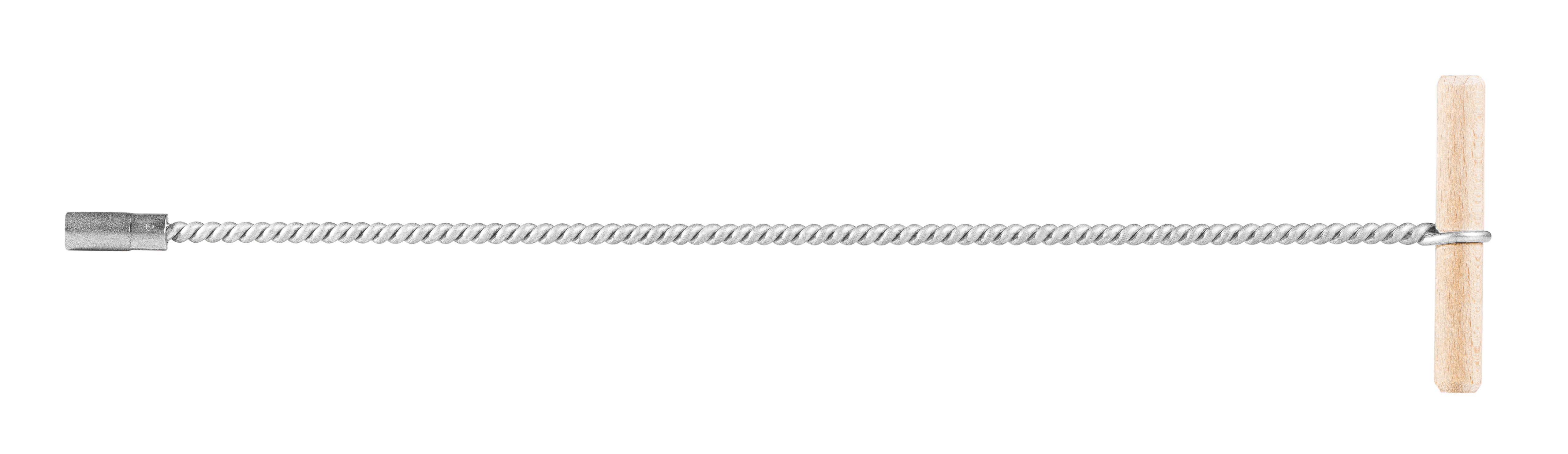

- Accessories dedicated for deep anchoring (brushes, extensions, piston plug, air adater and power guns)

Product information

Product Code |

Resin |

Description / Resin Type |

Volume |

[ml] | |||

R-KEX-I-600 |

R-KEX I |

Epoxy Resin |

600 |

Base material

-

Non-cracked concrete C20/25-C50/60

-

Cracked concrete C20/25-C50/60

Applications

- Safety barriers

- Formwork support systems

- Structural steelwork

- Street lamps

- Curtain walling

- Racking systems

- Balustrading

- Barriers

- Cladding restraints

- Masonry support

- Heavy machinery

- Platforms

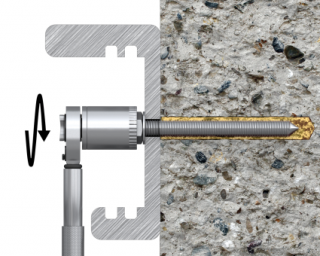

Installation guide

- Drill hole to the required diameter and depth for stud size being used.

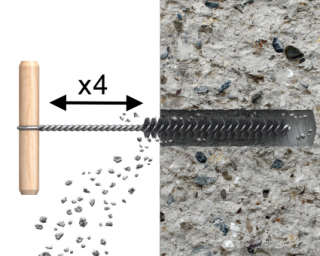

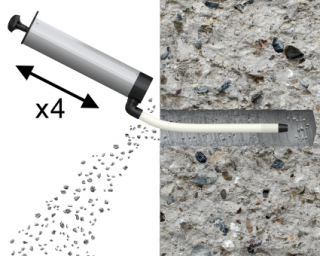

- Clean the hole thoroughly with brush and hand pump at least four times before installation.

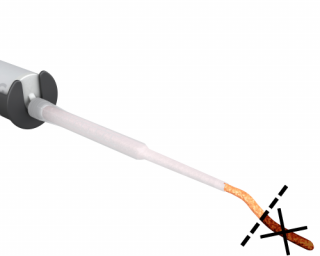

- Insert cartridge into gun and attach nozzle.

- Dispense to waste until even colour is obtained.

- Insert the mixing nozzle to the far end of the hole and inject resin, slowly withdrawing the nozzle as the hole is filled to 70% of its depth.

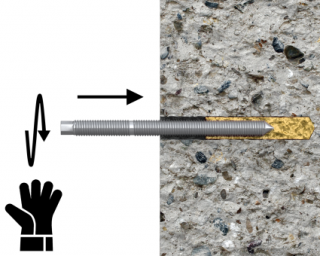

- Immediately insert the stud, slowly and with slight twisting motion. Remove any excess resin around the hole before it sets and leave it undisturbed until the curing time elapses.

- Attach fixture and tighten the nut to the required torque.

Installation data

R-STUDS

Size |

M8 |

M10 |

M12 |

M16 |

M20 |

M24 |

M30 |

||

Thread diameter |

d |

[mm] |

8 |

10 |

12 |

16 |

20 |

24 |

30 |

Hole diameter in substrate |

d0 |

[mm] |

10 |

12 |

14 |

18 |

24 |

28 |

35 |

Hole diameter in fixture |

df |

[mm] |

9 |

12 |

14 |

18 |

22 |

26 |

32 |

Min. hole depth in substrate |

h0 |

[mm] |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

Min. substrate thickness |

hmin |

[mm] |

hnom + 30 ≥ 100 |

hnom + 30 ≥ 100 |

hnom + 30 ≥ 100 |

hnom + 2d0 |

hnom + 2d0 |

hnom + 2d0 |

hnom + 2d0 |

Installation torque |

Tinst |

[Nm] |

10 |

20 |

40 |

80 |

120 |

160 |

200 |

Min. spacing |

smin |

[mm] |

40 |

40 |

40 |

40 |

50 |

50 |

60 |

Min. edge distance |

cmin |

[mm] |

40 |

40 |

40 |

40 |

50 |

50 |

60 |

MINIMUM EMBEDMENT DEPTH | |||||||||

Min. installation depth |

hnom,min |

[mm] |

60 |

60 |

70 |

80 |

90 |

96 |

120 |

MAXIMUM EMBEDMENT DEPTH | |||||||||

Min. installation depth |

hnom, max |

[mm] |

160 |

200 |

240 |

320 |

400 |

480 |

600 |

Minimum working and curing time

Resin temperature |

Concrete temperature |

Curing time* |

Working time |

[°C] |

[°C] |

[min] |

[min] |

5 |

5 |

96 h |

180 |

10 |

10 |

72 h |

120 |

20 |

20 |

10 h |

50 |

25 |

30 |

5 h |

35 |

25 |

40 |

4 h |

20 |