R-KER-II-S Hybrid resin with Post-Installed Rebar

High performance hybrid resin approved for use with post-installed rebar connections

Features and benefits

- Approved for use with post-installed rebars in concrete (EAD 330087-00-0601)

- Very high load capacity

- Suitable for use in dry or wet substrates and water filled holes

- Rapid bonding time enables quick execution of works

- Winter version can be used in warmer temperatures for faster curing

- No need for hole cleaning when using Dustlessdrill bit

- Tests in fire conditions confirm the fire resistance up to R120

Product information

Product Code |

Resin |

Description / Resin Type |

Volume |

[ml] | |||

R-KER-II-300-S |

R-KER-II-S |

R-KER II Hybrid Resin for High Temperature (Summer) / Slow Cure Styrene Free Hybrid Resin |

300 |

R-KER-II-400-S |

R-KER-II-S |

R-KER II Hybrid Resin for High Temperature (Summer) / Slow Cure Styrene Free Hybrid Resin |

400 |

Base material

-

Concrete C12/15-C50/60

Applications

- Post-installed rebar connections

- Rebar

- Rebar missed-outs

- Extending existing buildings and structures.

- Renovation and modrnization of bridges, buildings.

- Platforms

- Safety barriers

- Barriers

Installation guide

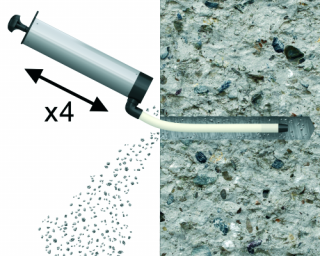

- Drill hole to the required diameter and depth for rebar size being used.

- Clean the drill hole thoroughly with brush and hand pump at least four times before installation

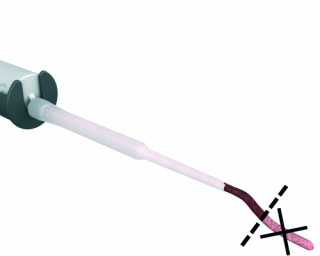

- Insert cartridge into gun and attach nozzle.

- Dispense to waste until even colour is obtained (min. 10 cm)

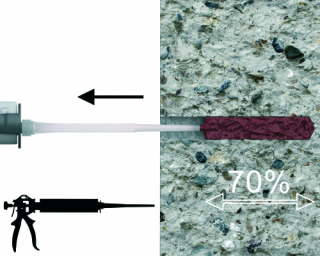

- Insert the mixer nozzle to the bottom of the drill hole and inject resin, slowly withdrawing the nozzle as the hole is filled to 70% of its depth.

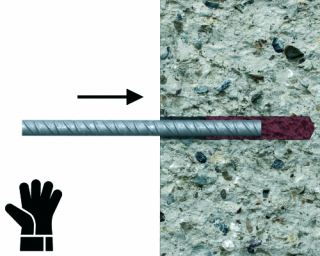

- Immediately insert the rebar, slowly and with slight twisting motion. Remove any excess resin around the hole before it sets and leave it undisturbed until the curing time elapses.

Installation data

POST INSTALLED REBARS

Size |

Ø8 |

Ø10 |

Ø12 |

Ø14 |

Ø16 |

Ø20 |

Ø25 |

Ø28 |

Ø32 |

Ø40 |

||

Rebar diameter |

ds |

[mm] |

8 |

10 |

12 |

14 |

16 |

20 |

25 |

28 |

32 |

40 |

Hole diameter in substrate |

d0 |

[mm] |

12 |

14 |

16 |

18 |

20 |

25 |

30 |

35 |

40 |

50 |

Brush diameter |

[mm] |

14 |

16 |

20 |

20 |

24 |

28 |

37 |

37 |

42 |

52 |

|

Min. anchorage length |

lb, min. |

[mm] |

115 |

145 |

170 |

200 |

230 |

285 |

355 |

400 |

455 |

570 |

Min. lap length (overlap splice) |

l0, min. |

[mm] |

200 |

215 |

255 |

300 |

340 |

430 |

540 |

600 |

690 |

860 |

Max. anchorage length |

lv, max. |

[mm] |

400 |

500 |

600 |

700 |

800 |

1000 |

1200 |

1400 |

1500 |

1000 |

Minimum working and curing time

R-KER-II S

Resin temperature |

Concrete temperature |

Curing time* |

Working time |

[°C] |

[°C] |

[min] |

[min] |

5 |

5 |

12 h |

40 |

10 |

10 |

8 h |

20 |

15 |

15 |

6 h |

15 |

20 |

20 |

4 h |

10 |

25 |

25 |

3 h |

9.5 |

25 |

30 |

2 h |

7 |

25 |

35 |

2 h |

6.5 |

25 |

40 |

1.5 h |

6.5 |

*For wet concrete the curing time must be doubled