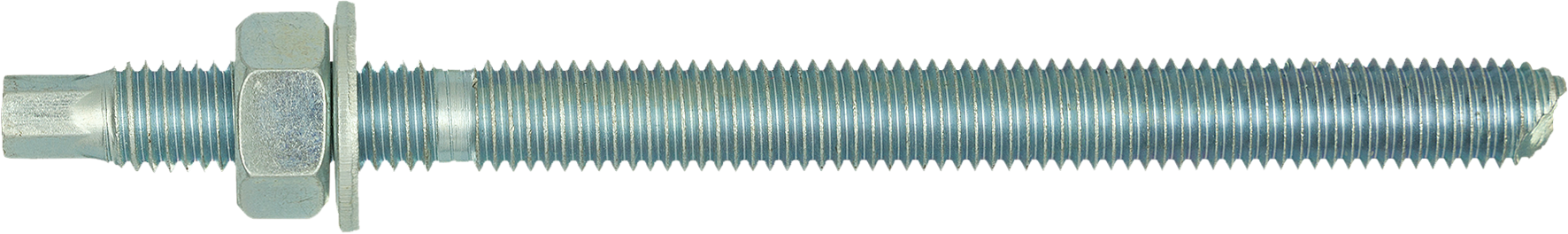

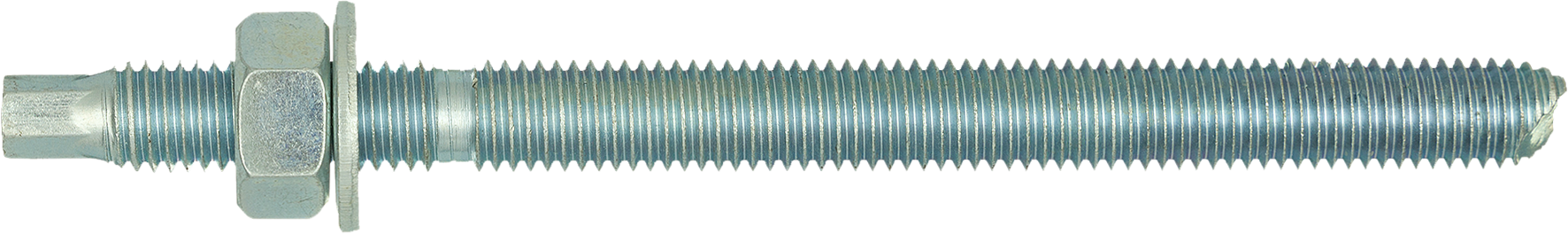

R-KER-II Hybrid resin with Threaded Rods

High strength and versatile application in cracked and non-cracked concrete with threaded rods.

Features and benefits

- Approved for use in cracked and non-cracked concrete (EAD 330499-01-0601), working life up to 100 years

- Suitable for use in dry or wet substrates and water filled holes

- For faster curing winter version of the resin can be used

- No need for hole cleaning when using Dustlessdrill bit

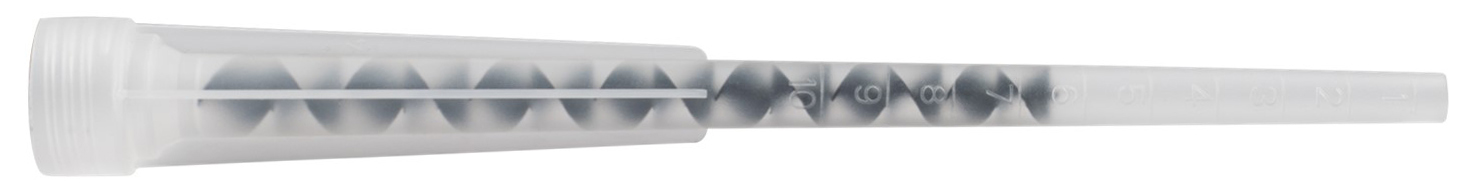

- Special nozzle with longer mixer for more comfortable and precise application

- Suitable for multiple use. Partly used product can be reused after fitting new nozzle

- Very high load capacity

- Tests in fire conditions confirm the fire resistance up to R120

Product information

Product Code |

Resin |

Description / Resin Type |

Volume |

[ml] | |||

R-KER-II-300 |

R-KER-II |

R-KER II Hybrid Resin |

300 |

R-KER-II-345 |

R-KER-II |

R-KER II Hybrid Resin |

345 |

R-KER-II-400 |

R-KER-II |

R-KER II Hybrid Resin |

400 |

R-KER-II-300-S |

R-KER-II-S |

R-KER II Hybrid Resin for High Temperature (Summer) / Slow Cure Styrene Free Hybrid Resin |

300 |

R-KER-II-400-S |

R-KER-II-S |

R-KER II Hybrid Resin for High Temperature (Summer) / Slow Cure Styrene Free Hybrid Resin |

400 |

R-KER-II-300-W |

R-KER-II-W |

R-KER II Hybrid Resin for Low Temperature (Winter) / Rapid Cure Styrene Free Hybrid Resin |

300 |

R-KER-II-400-W |

R-KER-II-W |

R-KER II Hybrid Resin for Low Temperature (Winter) / Rapid Cure Styrene Free Hybrid Resin |

400 |

R-KER-II-300-SV |

R-KER-II |

R-KER II Hybrid Resin |

300 |

R-KER-II-400-FR |

R-KER-II |

R-KER II Hybrid Resin |

400 |

R-KER-II-300-FR |

R-KER-II |

R-KER II Hybrid Resin |

300 |

Base material

-

Cracked concrete C20/25-C50/60

-

Non-cracked concrete C20/25-C50/60

Applications

- Curtain walling

- Balustrading

- Handrails

- Canopies

- Cable conduits and trays

- Fencing & gates manufacturing and installation

- Pipework/ductwork supports

- Platforms

- Pipelines systems

- Passenger lifts

- Safety barriers

- Formwork support systems

- Structural steelwork

- Street lamps

- Racking systems

- Barriers

- Cladding restraints

- Heavy machinery

Installation guide

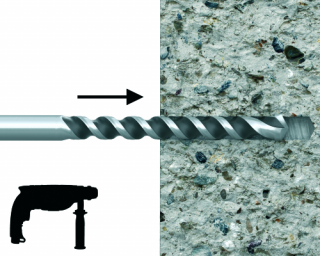

- Drill hole to the required diameter and depth for stud size being used.

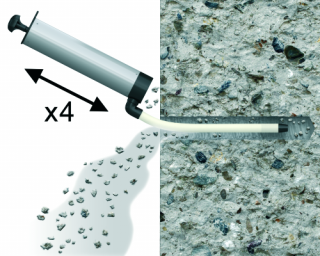

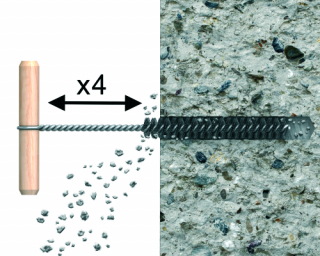

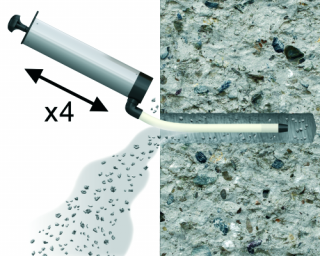

- Clean the hole thoroughly with brush and hand pump at least four times before installation.

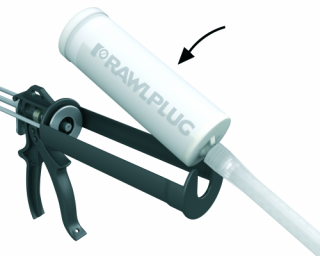

- Insert cartridge into gun and attach nozzle.

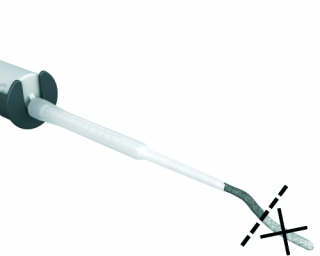

- Dispense to waste until even colour is obtained (min. 10 cm).

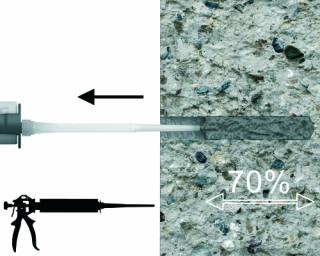

- Insert the mixer nozzle to the bottom of the drill hole and inject resin, slowly withdrawing the nozzle as the hole is filled to 70% of its depth.

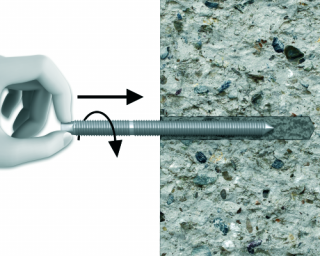

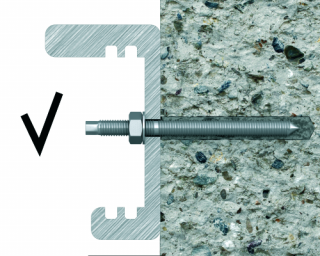

- Immediately insert the stud, slowly and with slight twisting motion. Remove any excess resin around the hole before it sets and leave it undisturbed until the curing time elapses.

- Attach fixture and tighten the nut to the required torque.

Installation data

R-STUDS

Size |

M8 |

M10 |

M12 |

M16 |

M20 |

M24 |

M30 |

||

Thread diameter |

d |

[mm] |

8 |

10 |

12 |

16 |

20 |

24 |

30 |

Hole diameter in substrate |

d0 |

[mm] |

10 |

12 |

14 |

18 |

24 |

28 |

35 |

Hole diameter in fixture |

df |

[mm] |

9 |

12 |

14 |

18 |

22 |

26 |

33 |

Min. hole depth in substrate |

h0 |

[mm] |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

Min. substrate thickness |

hmin |

[mm] |

hnom + 30 ≥ 100 |

hnom + 30 ≥ 100 |

hnom + 30 ≥ 100 |

hnom + 2d0 |

hnom + 2d0 |

hnom + 2d0 |

hnom + 2d0 |

Installation torque |

Tinst |

[Nm] |

10 |

20 |

40 |

80 |

120 |

160 |

200 |

Min. spacing |

smin |

[mm] |

40 |

40 |

40 |

40 |

40 |

50 |

60 |

Min. edge distance |

cmin |

[mm] |

40 |

40 |

40 |

40 |

40 |

50 |

60 |

MINIMUM EMBEDMENT DEPTH | |||||||||

Min. installation depth |

hnom,min |

[mm] |

60 |

60 |

60 |

60 |

80 |

96 |

120 |

MAXIMUM EMBEDMENT DEPTH | |||||||||

Min. installation depth |

hnom, max |

[mm] |

160 |

200 |

240 |

320 |

400 |

480 |

600 |

Minimum working and curing time

R-KER-II

Resin temperature |

Concrete temperature |

Curing time* |

Working time |

[°C] |

[°C] |

[min] |

[min] |

5 |

-5 |

24 h |

40 |

5 |

0 |

3 h |

30 |

5 |

5 |

90 |

15 |

10 |

10 |

60 |

8 |

15 |

15 |

60 |

5 |

20 |

20 |

45 |

2.5 |

25 |

25 |

45 |

2 |

25 |

30 |

45 |

2 |

25 |

35 |

30 |

1.5 |

25 |

40 |

30 |

1.5 |

*For wet concrete the curing time must be doubled

R-KER-II S

Resin temperature |

Concrete temperature |

Curing time* |

Working time |

[°C] |

[°C] |

[min] |

[min] |

5 |

5 |

12 h |

40 |

10 |

10 |

8 h |

20 |

15 |

15 |

6 h |

15 |

20 |

20 |

4 h |

10 |

25 |

25 |

3 h |

9.5 |

25 |

30 |

2 h |

7 |

25 |

35 |

2 h |

6.5 |

25 |

40 |

1.5 h |

6.5 |

*For wet concrete the curing time must be doubled

R-KER-II W

Resin temperature |

Concrete temperature |

Curing time* |

Working time |

[°C] |

[°C] |

[min] |

[min] |

5 |

-20 |

24 h |

80 |

5 |

-15 |

16 h |

60 |

5 |

-10 |

8 h |

40 |

5 |

-5 |

4 h |

20 |

5 |

0 |

2 h |

14 |

5 |

5 |

60 |

9 |

10 |

10 |

45 |

5.5 |

15 |

15 |

30 |

3 |

20 |

20 |

15 |

2 |

25 |

25 |

10 |

1.5 |

25 |

30 |

10 |

1.5 |

25 |

35 |

5 |

1 |

25 |

40 |

5 |

1 |

*For wet concrete the curing time must be doubled