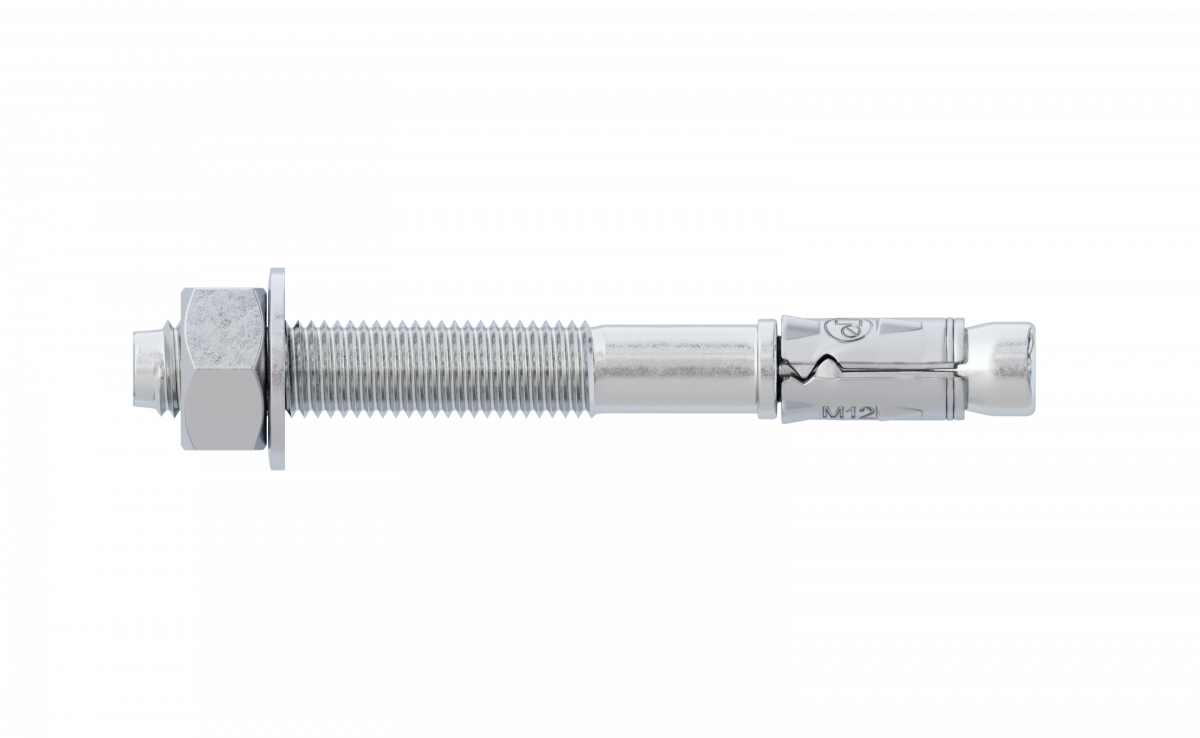

R-HPTIIIZP Zinc Plated Throughbolt

Throughbolt anchor with corrosion-resistant coating for cracked and non-cracked concrete

Features and benefits

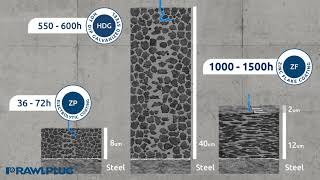

- A new generation of band anchors with a galvanized zinc coating

- High performance in cracked and non-cracked concrete confirmed by ETA Option 1

- Highest quality ensures maximum load capability

- For applications requiring fire resistance up to 120 minutes

- Suitable for reduced embedment to avoid contact with reinforcement

- Embedment depth markings help to ensure precise installation of the anchor

- Design of R-HPTII allows drilling and installing directly through the fixture and helps to reduce installation time

- Fire resistant

- Anchors can be used in earthquake risk zones - seismic category C1 and C2

- Adjustable embedment depth in cracked and uncracked concrete C20/25-C50/60

- The new geometry of the expansion band with an additional ring at its end ensures optimal contact with the concrete

- Small distances from the edge of the concrete and between the anchors

- Optimized cone shape to increase the angle of attack of the band on the ground, which translates into greater load capacity of the anchor in concrete

- Anchor length identification mark to identify embedment length/depth. Facilitates post-installation inspection.

- factories in Europe, with experience in the automotive and industrial sectorsmingScrews are produced in one of the largest and most renowned cold for

- The production of concrete screwes takes place on bar stock, manufactured in a Polish steel mill

Product information

Size |

Product Code |

Anchor |

Fixture |

||

Diameter |

Length |

Max. thickness |

Hole diameter |

||

d |

L |

tfix |

df |

||

[mm] |

[mm] |

[mm] |

[mm] |

||

M8 |

R-HPTIIIZP08060/10 |

8 |

60 |

10 |

9 |

R-HPTIIIZP08075/25 |

8 |

75 |

25 |

9 |

|

R-HPTIIIZP08085/35 |

8 |

85 |

35 |

9 |

|

R-HPTIIIZP08095/45 |

8 |

95 |

45 |

9 |

|

R-HPTIIIZP08105/55 |

10 |

105 |

55 |

9 |

|

R-HPTIIIZP08115/65 |

8 |

115 |

65 |

9 |

|

M10 |

R-HPTIIIZP10065/5 |

10 |

65 |

5 |

12 |

R-HPTIIIZP10080/20 |

10 |

80 |

20 |

12 |

|

R-HPTIIIZP10095/35 |

10 |

95 |

35 |

12 |

|

R-HPTIIIZP10130/70 |

10 |

130 |

70 |

12 |

|

M12 |

R-HPTIIIZP12080/5 |

12 |

80 |

5 |

14 |

R-HPTIIIZP12100/25 |

12 |

100 |

25 |

14 |

|

R-HPTIIIZP12115/40 |

12 |

115 |

40 |

14 |

|

R-HPTIIIZP12125/50 |

12 |

120 |

50 |

14 |

|

R-HPTIIIZP12135/60 |

12 |

135 |

60 |

14 |

|

R-HPTIIIZP12150/75 |

12 |

150 |

75 |

14 |

|

Base material

-

Cracked concrete C20/25-C50/60

-

Non-cracked concrete C20/25-C50/60

-

Reinforced concrete

-

Unreinforced concrete

For use also with

-

Natural Stone (after site testing)

Applications

- Cladding restraints

- Consoles

- Barriers

- Structural steel

- Curtain walling

- Handrails

- Heavy Plant

- Balustrading

- Passenger lifts

- Facades

- Racking systems

- Platforms

- Fencing & gates manufacturing and installation

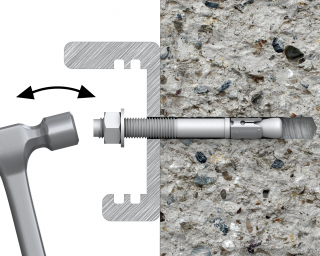

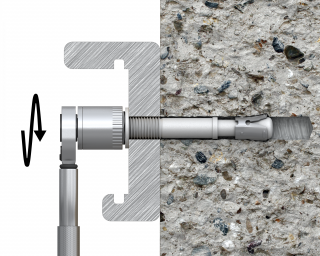

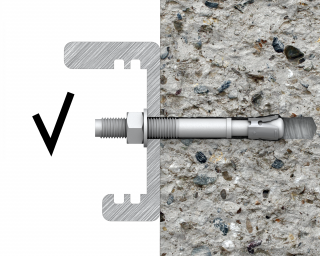

Installation guide

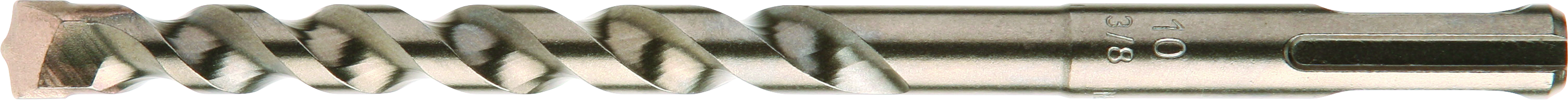

- Drill a hole of required diameter and depth

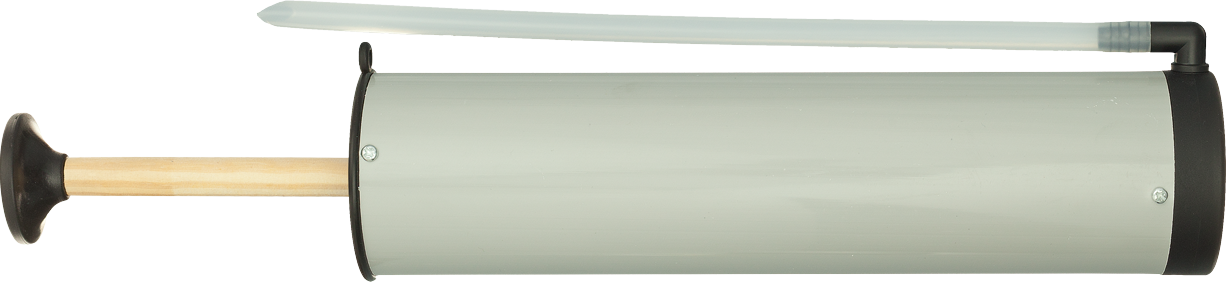

- Clear the hole of drilling dust and debris (using blowpump or equivalent method)

- Lightly tap the throughbolt through the fixture into hole with a hammer, until fixing depth is reached

- Tighten to the recommended torque

Installation data

Size |

M8 |

M10 |

M12 |

||

Thread diameter |

d |

[mm] |

8 |

10 |

12 |

Hole diameter in substrate |

d0 |

[mm] |

8 |

10 |

12 |

Installation torque |

Tinst |

[Nm] |

15 |

40 |

50 |

Wrench size |

Sw |

[mm] |

13 |

17 |

19 |

External diameter of washer |

[mm] |

16 |

20 |

24 |

|

STANDARD EMBEDMENT DEPTH | |||||

Min. hole depth in substrate |

h0,s |

[mm] |

60 |

73 |

88 |

Min. installation depth |

hnom,s |

[mm] |

55 |

68 |

80 |

Min. substrate thickness |

hmin,s |

[mm] |

100 |

120 |

140 |

REDUCED EMBEDMENT DEPTH | |||||

Min. hole depth in substrate |

h0,r |

[mm] |

45 |

53 |

68 |

Min. installation depth |

hnom,r |

[mm] |

40 |

48 |

60 |

Min. substrate thickness |

hmin,r |

[mm] |

80 |

80 |

100 |

Min. edge distance |

cmin |

[mm] |

40 |

45 |

55 |

Min. spacing |

smin |

[mm] |

35 |

40 |

50 |