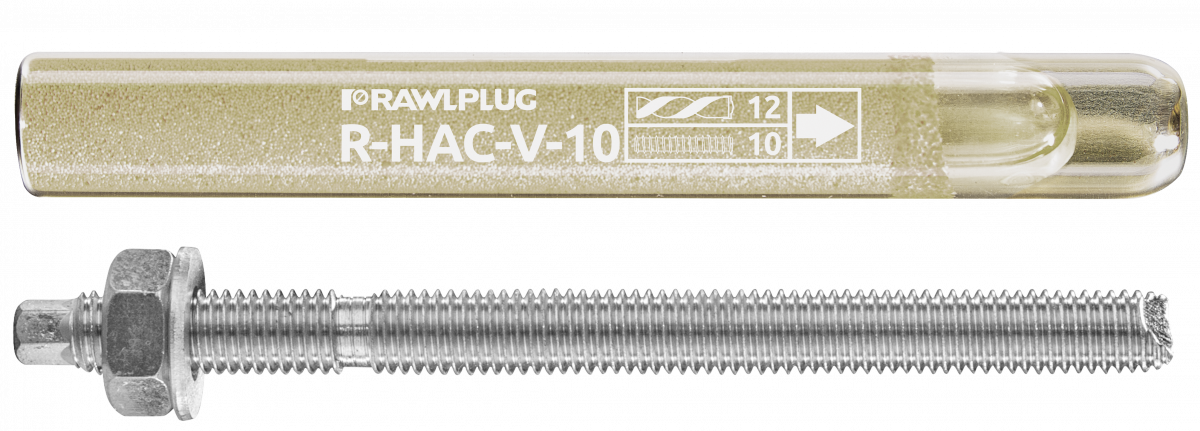

R-HAC-V Hammer-In with Threaded Rods

Heavy duty anchor with small spacing and edge distances, simply installed by hammering the threaded rods

Features and benefits

- High performance anchor, for use in safety critical applications

- The system relies on the adhesion between concrete and resin, which is free from expansion forces. This makes it an ideal choice where close edge and spacing distances are required

- Capsule contains precise amounts of ingredients making it a very consistent product

- Adhesive bond strength is not affected by unpolluted water

- Suitable for dry or wet non-cracked concrete

- Low cost tooling required for installation, quick and easy to install

- Styrene free - virtually odourless

- Approved for use with threaded rods in non-cracked concrete (ETAG001 Option 7)

Product information

Product Code |

Description / Resin Type |

R-HAC-V-08 |

Styrene Free Vinylester Resin |

R-HAC-V-10 |

Styrene Free Vinylester Resin |

R-HAC-V-12 |

Styrene Free Vinylester Resin |

R-HAC-V-16 |

Styrene Free Vinylester Resin |

R-HAC-V-20 |

Styrene Free Vinylester Resin |

R-HAC-V-24 |

Styrene Free Vinylester Resin |

R-HAC-V-30 |

Styrene Free Vinylester Resin |

Base material

-

Non-cracked concrete C20/25-C50/60

For use also with

-

Natural Stone (after site testing)

Applications

- Balustrading & handrails

- Cable trays

- Guard rails

- Heavy machinery

- Threaded rods

- Cladding restraints

- Curtain walling

- Fencing & gates manufacturing and installation

- Reinforcement bars

Installation guide

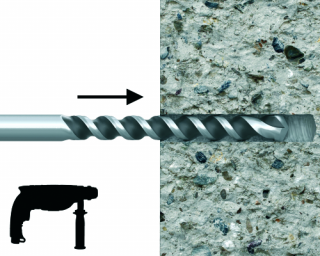

- Drill hole to the required diameter and depth for stud size being used.

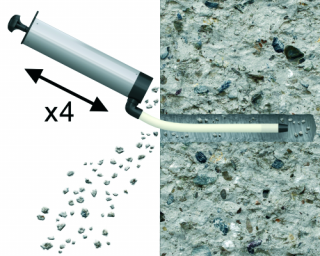

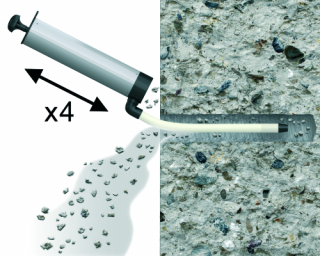

- Clean the hole thoroughly with brush and hand pump at least four times before installation.

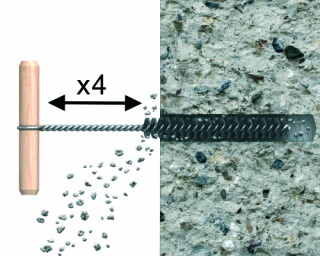

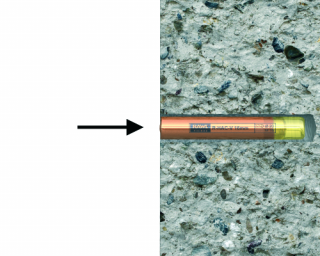

- Insert capsule into the hole.

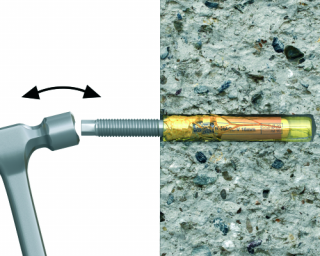

- The stud is simply hammered through the capsule using a manual or mechanical hammer (M16-M30).

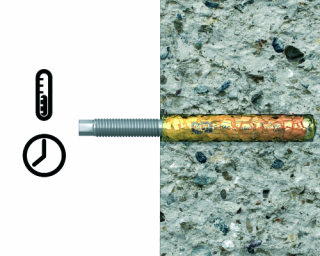

- Leave the anchor undisturbed unitl the curing time elapses.

- Attach fixture and tighten the nut to the required torque.

Installation data

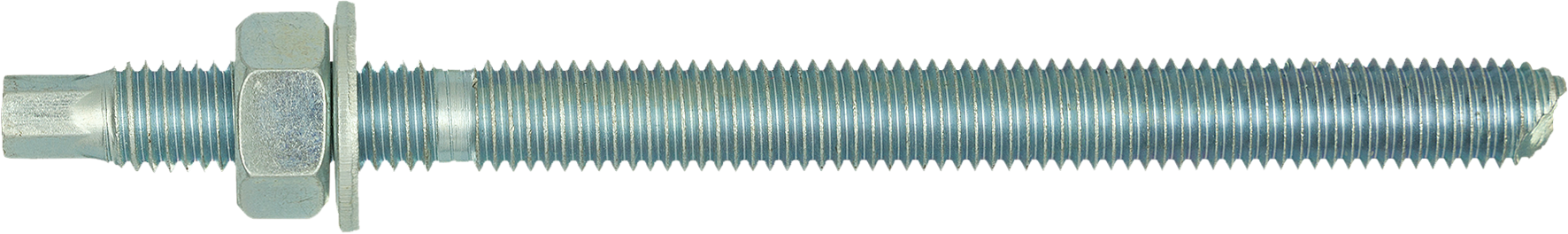

R-STUDS

Size |

M8 |

M10 |

M12 |

M16 |

M20 |

M24 |

M30 |

||

Thread diameter |

d |

[mm] |

8 |

10 |

12 |

16 |

20 |

24 |

30 |

Hole diameter in substrate |

d0 |

[mm] |

10 |

12 |

14 |

18 |

24 |

28 |

35 |

Capsule size |

[mm] |

8 |

10 |

12 |

16 |

20 |

24 |

30 |

|

Capsule diameter |

dc |

[mm] |

9.25 |

10.75 |

12.65 |

16.75 |

21.55 |

23.75 |

33.2 |

Installation torque |

Tinst |

[Nm] |

10 |

20 |

40 |

80 |

120 |

180 |

300 |

Min. hole depth in substrate |

h0 |

[mm] |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

Min. installation depth |

hnom |

[mm] |

80 |

90 |

110 |

125 |

170 |

210 |

270 |

Min. substrate thickness |

hmin |

[mm] |

120 |

130 |

140 |

180 |

230 |

270 |

340 |

Min. spacing |

smin |

[mm] |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

Min. edge distance |

cmin |

[mm] |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

0.5 * hnom ≥ 40 |

Minimum working and curing time

Resin temperature |

Concrete temperature |

Curing time* |

Working time |

[°C] |

[°C] |

[min] |

[min] |

5 |

-5 |

1440 |

- |

5 |

0 |

840 |

- |

5 |

5 |

240 |

- |

10 |

10 |

180 |

- |

15 |

15 |

90 |

- |

20 |

20 |

45 |

- |

25 |

30 |

20 |

- |

25 |

40 |

10 |

- |